Clarifying membrane filtration concentration system is a high-precision, cross-flow membrane filtration system developed and designed by our company according to the technical requirements of clarifying filtration for juice, health wine, oral liquid, aged vinegar and soy sauce. This system has the technical characteristics of high filtering accuracy, low operating pressure, easy cleaning and maintenance, low energy consumption, wide application range, etc., especially suitable for filtering beverage, beverage and condiment with filtering accuracy requirements.

The equipment parameters

Equipment model | Processing | Minimum circulation volume | Operating pressure | Operating temperature | Note |

JC-MZ-40-1X | 50-100L/h | 10L | ≤0.2MPa | <45℃ | |

JC-MZ-40-2X | 150-200L/h | 20L | ≤0.2MPa | <45℃ | |

JC-MZ-40-4X | 300-400L/h | 40L | ≤0.2MPa | <45℃ | |

JC-MZ-40-6X | 400-500L/h | 50L | ≤0.2MPa | <45℃ | |

JC-MZ-90-2X | 0.5-0.8T/h | 60L | ≤0.2MPa | <45℃ | |

JC-MZ-90-4X | 0.8-1.0T/h | 100L | ≤0.2MPa | <45℃ | |

JC-MZ-90-6X | 1.3-1.5T/h | 150L | ≤0.2MPa | <45℃ | |

JC-MZ-90-8X | 1.8-2.0T/h | 200L | ≤0.2MPa | <45℃ | |

JC-MZ-90-10X | 2.3-2.5T/h | 240L | ≤0.2MPa | <45℃ | |

JC-MZ-90-12X | 2.8-3.0T/h | 280L | ≤0.2MPa | <45℃ |

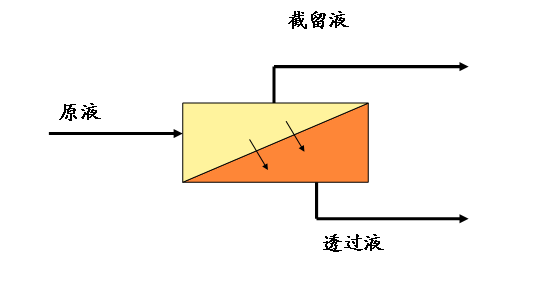

Membrane is a kind of polymer material with special selective separation function, which can separate the fluid into two parts that are not connected, so that one or several substances can pass through, and the other substances can be separated. Membrane separation technology with its high efficiency, energy saving, environmental protection and high precision separation characteristics, has been widely used in medicine, chemical industry, electronics, food, environmental protection and other fields, has become one of the major industrial technologies in the 21st century.

Membrane separation method refers to the method of separating solid from liquid and molecule from molecule according to cross-flow filtration according to the principle of sieving with pressure as the driving force and semi-permeable membrane as the filtration layer, according to the molecular size, configuration and electrical polarity of the material. The core of membrane separation is the membrane itself, which needs to be semi-permeable, that is, able to pass through one substance and obstruct another.

Membrane technology and membrane separation and concentration technology based on polymer materials science have some advantages that traditional separation and concentration technology cannot compare with:

High separation precision, good separation and concentration effect, high work efficiency;

Pure physical process, no chemical reaction, no secondary pollution;

Cross-flow operation process, better solve the problem of pollution blockage, prolong the cleaning cycle;

The membrane module has a large filling area, a large amount of infiltration, and a small footprint, which can reduce the investment of hardware facilities.

The separation process has no phase transition, low energy consumption and meets the requirements of clean production for energy saving and emission reduction.

The membrane can be cleaned and reused repeatedly with a service life of 2-3 years to reduce the consumption cost.

High degree of automation, reduce labor intensity and reduce labor cost;

Scope of business

Ceramic membrane, stainless steel membrane, organic tube membrane, roll membrane, reverse osmosis membrane, microfiltration/ultrafiltration/nanofiltration technology and equipment

Application field

1. Biological fermentation

Degerming, clarifying, purifying and concentrated desalting of fermentation liquor;

Lower column liquid removal, concentration, etc.;

Application cases: cefore-intermediate, amino acid, coloonic acid, vancomycin, protease, escherichia coli active protein, amylase;

2. Plant extraction

Traditional Chinese medicine plant is leaching solvent into the medicinal materials, transfer the effective components from the solid phase to liquid phase separation process, traditional process of low accuracy, high solvent consumption, high cost of enrichment process, such as the introduction of advanced membrane system provides the separation and purification technology for its industrial production, energy saving, water saving and emissions reduction, reliable means of clean and environmental protection.

Problem solving:

Purification of impurities: remove the soluble impurities in the liquid after centrifuge separation, such as colloids, proteins, tannins and other impurities, improve the quality, with a high degree of clarity, macromolecules have a good intercession effect.

Energy saving: reduce energy consumption. Membrane concentration costs only 2-10 yuan/ton of water, while traditional concentration costs 80-100 yuan/ton of water.

Recycling: membrane concentrated dialysis water can be reused to the extraction process to improve the utilization of water resources.

Application case:

Honeysuckle, ginseng, astragalus, panax notoginseng, radix isatidis, ginkgo biloba, rhubarb, double rhizoma coptidis, salvia miltiorrhiza, xiangdan, forsythia, erigeron breviscapus, houttuynia and other plant extracts clarify, remove impurities, decolorise and concentrate, Chinese medicine injection in addition to heat source and tannin, reduce allergic reaction.

Stevia sugar purification and concentration, allicin, purification and concentration, gardenia yellow pigment purification and concentration, radish red pigment purification and concentration, sugar beet red pigment purification and enrichment, ginseng saponins concentration and purification of resveratrol, lamps, purification and concentration, flavonoids purification and concentration, brown alga of purification and enrichment and purification of tea polyphenols, caffeine and enrichment.

3. TCM preparation

Degerming, removing impurities, clarifying and filtering of traditional Chinese medicine oral liquid;

Clarification, filtration, removal of impurities and heat sources of traditional Chinese medicine injections and ointments;

Clarification, impurity removal and concentration dehydration of traditional Chinese medicine extract;

Application case:

Shenkang injection, shenmai injection, baicalin injection, shuanghuanglian injection, aidi injection, cancer xiaoping injection, shengmaiyin oral liquid, qingre oral liquid for children, morindi oral liquid, shengsheng oral liquid, etc.

4. Alcohol

Liquor clarification, decolorization, sterilization and filtration;

Health wine clarification and filtration to solve the secondary precipitation;

Rice wine clarification filtration;

Beer clarification, germicidal filtration, beer storage tank bottom waste liquid recovery beer and yeast;

Wine body clarifies, sterilizes and filters;

Application case:

Green plum wine, red bayberry wine, roxburgh-pear wine, kiwi fruit wine, mulberry fruit wine, FIG wine, rice wine, beer, etc.

Fruit and vegetable drinks

Fruit and vegetable juice clarification filtration;

Clarification and concentration of concentrated fruit and vegetable juice;

Enzyme clarification and sterilizing filtration;

Fruit vinegar clarification filtration;

Herbal tea clarification, filtration and concentration;

Application case:

Herbal tea, functional tea, beverage tea, concentrated tea, instant tea, apple juice, orange juice, pear juice, watermelon juice, lemon juice, sour Angle juice, olive juice, fruit vinegar, enzymes, etc.

6. Active protein/enzyme preparation/antibody

Enzyme preparation clarification and concentration desalination;

Concentration and dehydration of collagen, plasma protein and antibody;

Application case:

Antibody, collagen, synthetic peptide, plasma protein, animal complex protein, amylase, alkaline protease, etc.

7. Industrial water treatment

Preparation of pure water and ultrapure water by whole film method;

Pharmaceutical wastewater, pesticide wastewater, food wastewater, electroplating wastewater, chemical wastewater, printing and dyeing wastewater, plant extraction wastewater, acid and alkali wastewater, resin recycling wastewater, condensing wastewater, papermaking wastewater, cotton spinning wastewater and other industrial wastewater reuse treatment and standard discharge treatment;

Application case:

Preparation of purified water, ultrapure water and water for injection by full-film method;

Recovery and treatment of plant extraction wastewater by membrane method and standard discharge;

Recovering sugar and treating water by membrane method;

Standard treatment of glyphosate wastewater;

Acid and alkali recovery of resin regenerated wastewater.

Copyright © http://www.lnyaoji.com/Liaoyang city high jet vacuum equipment co., LTD. Welcome to inquire!